Chemical And Pharmaceutical Equipment Suppliers

Changshu Longyu Chemical Equipment Co., Ltd. was founded in 1997 and registered as its current name in 2009. The company is located at the west foot of Yushan Mountain in Changshu with beautiful scenery, on the west bank of Shanghu Lake with rippling blue waves, with Shanghai in the east, Wuxi in the west, Zhangjiagang in the north, and Suzhou in the south. The traffic is very convenient. The total area is 14,000 square meters, with more than 50 employees, including technical and management personnel, engineers, etc., with 3 invention patents and 19 utility model patents.

The company has passed the ISO9001 international quality system certification and has a D1.D2 level pressure vessel manufacturing license.

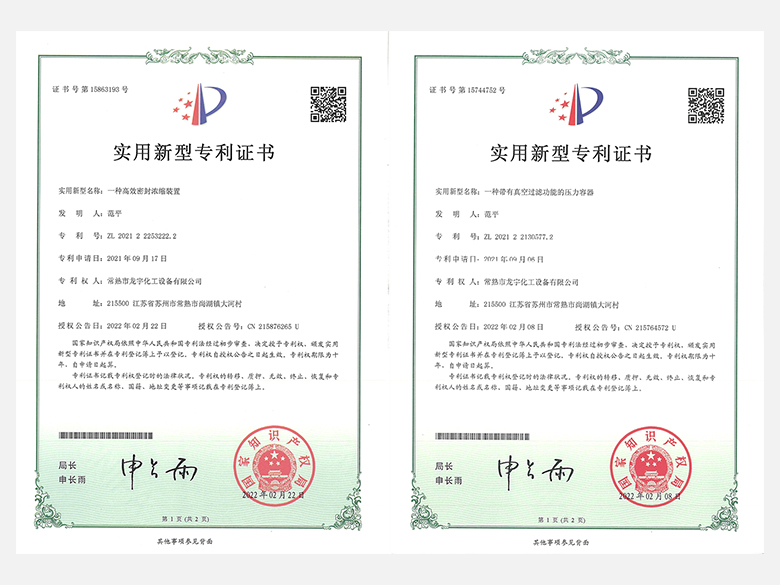

Patents View More

More than 20 years of technical experience

Have Managers and Engineers

Product independent research

3 invention patents, 19 utility model patents

Through quality certification and manufacturing license

Create reliable products for customers

Perfect after sale service

Continuously improve service quality as the pursuit

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn more

The company mainly manufactures I and II carbon steel and stainless steel pressure vessels, including reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produces civilian glycerin equipment and glass-lined equipment products, with a wide range of products. Used in petrochemical, pharmaceutical, food and power industries.

Learn moreR&D and Production of Chemical Equipment

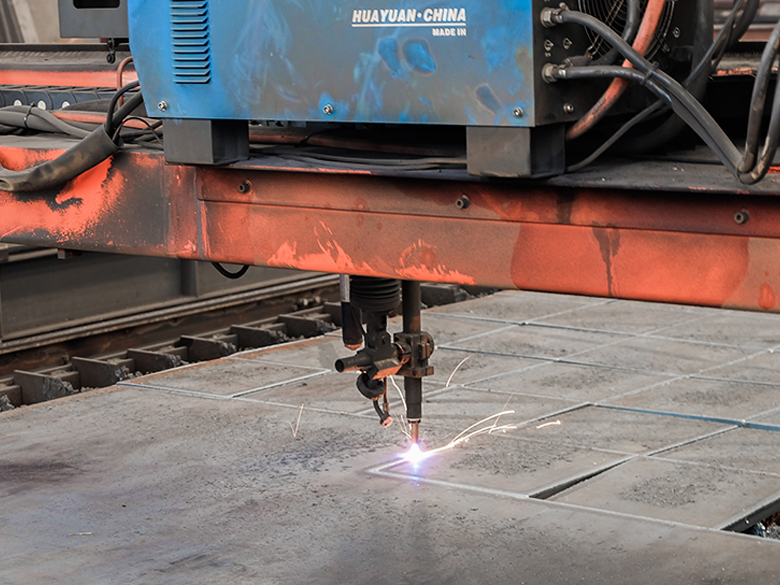

Covering an area of 14,000 square meters, the factory scale integrates from product research and development to finished product sales to ensure product quality.

With technical and management personnel, engineers 50 people.

With different mechanical processing equipment and testing equipment.

Invention Patent

Utility Model Patents

The company has passed the ISO9001 international quality system certification and has a D1.D2 level pressure vessel manufacturing license.

Products include reactors, heat exchangers, storage tanks, fermentation equipment, scraped film evaporators, towers, and also produce civilian glycerin equipment and glass-lined equipment products.

Adhere to technological innovation and promote the sustainable development of the company as the goal.

Products are widely used in petrochemical, pharmaceutical, food and power industries.

Has been sold to Guangdong, Inner Mongolia, Shandong, Hebei, Anhui, Zhejiang, Tianjin, Shanghai and other parts of the province, and has been exported to Thailand and other Southeast Asian countries.

The quality policy is "strengthen process control, produce high-quality products, manage continuous improvement, and ensure customer satisfaction".

Create reliable products for customers and improve service quality as the pursuit.

Strive to become a high-quality supplier of chemical and pharmaceutical equipment.

Be sincere and do things with heart

Jacketed reactor is a common chemical equipment, which has the functions of heating, cooling and thermal insulation. It is suitable for many industries. The following are some main application industries: 1. chemical industry: used for various chemical reactions, such as polymerization, esterification, hydrolysis, etc. For example, in the production of polymer materials such as plastics, rubber a

The stainless steel tower has the following characteristics: 1. strong corrosion resistance: stainless steel contains chromium, nickel and other alloy elements, can form a dense oxide film on the surface, effectively resist the erosion of air, water, acid and alkali and other substances, and can maintain good performance in harsh natural and industrial environments, is not easy to rust and corros

Deodorization tower is one of the key equipment in the oil refining process, which is mainly used to remove odor substances, free fatty acids and other impurities in the oil, so as to improve the quality and stability of the oil. The following is the general process of refining oil in the deodorizer:

Carbon steel spiral plate heat exchangers are mainly used in the following fields: 1. Petrochemical industry: used for preheating crude oil, condensing steam at the top of distillation tower, cooling residual oil at the bottom of vacuum tower, etc. in the process of petroleum refining; In chemical production, it can be used for heat exchange in various chemical reaction processes, such as cooling

Tower kettle reboiler is an important component in separation equipment such as distillation towers in chemical, petroleum and other fields. It is mainly used to provide heat for the materials inside the tower, partially vaporize the materials, and achieve separation or purification purposes. Its specific uses are reflected in the following aspects: 1. Provide gas-liquid mass transfer power

The hydrogen peroxide coalescer has the following applications in the chemical industry: 1. Production process of hydrogen peroxide Dehydration of residual solution: In the production of hydrogen peroxide by anthraquinone method, a certain amount of water will be carried in the top of the extraction tower. Through a coalescence separator, the turbid material can be coalesced to a clear and